Tungsten Steel Milling 4 Flute End Mill / 6mm 8mm 12mm Cutter End

Mill For Stainless Steel

Name: Hardened tungsten steel milling cutter

Spiral angle: 35 °

Coating: ALTin

Blade number: 4 Flute

Material: High quality bar

Applicable machine tools: CNC machining center, engraving machine,

high-speed machine, etc.

Materials used: die steel, tool steel, modulated steel, carbon

steel, cast steel, heat treated hardened steel, etc.

Main features: Germany Walter five-axis grinding machine, large

center diameter design, chip removal smooth, enhance tool rigidity,

not lack of angle; use fine grain grinding wheel processing, reduce

surface grinding wheel trace, coating treatment more uniform,

longer service life.

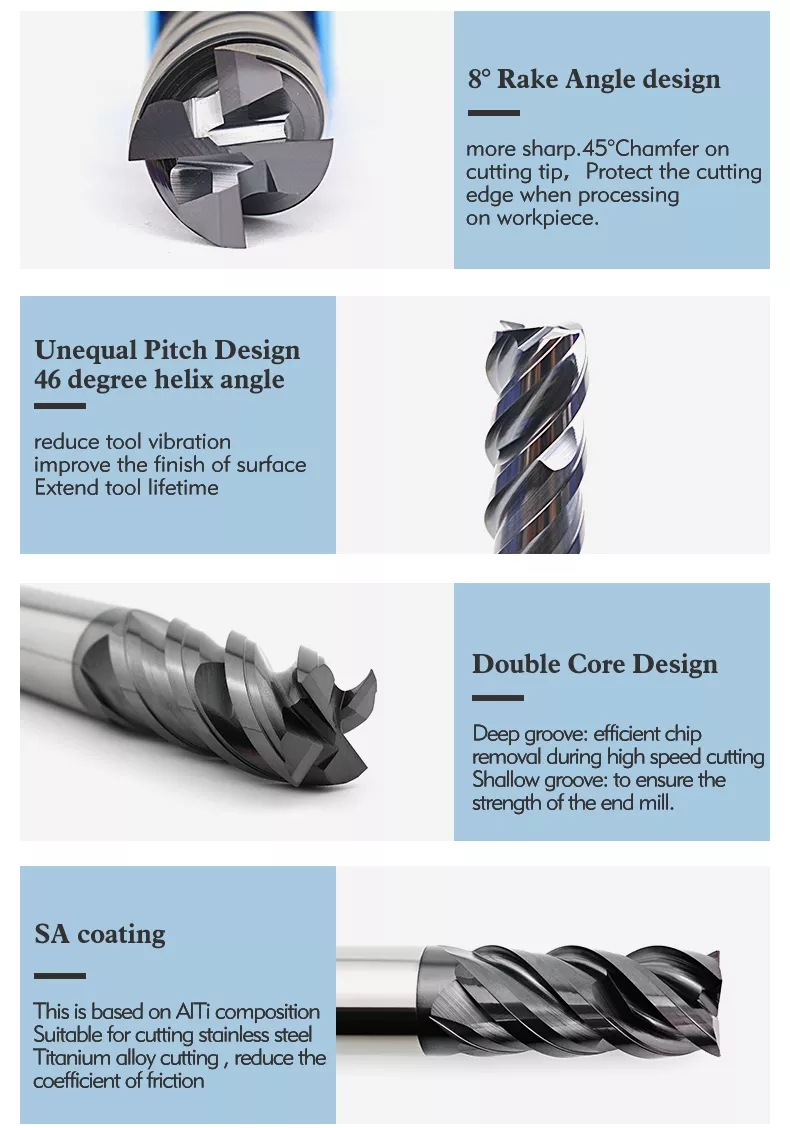

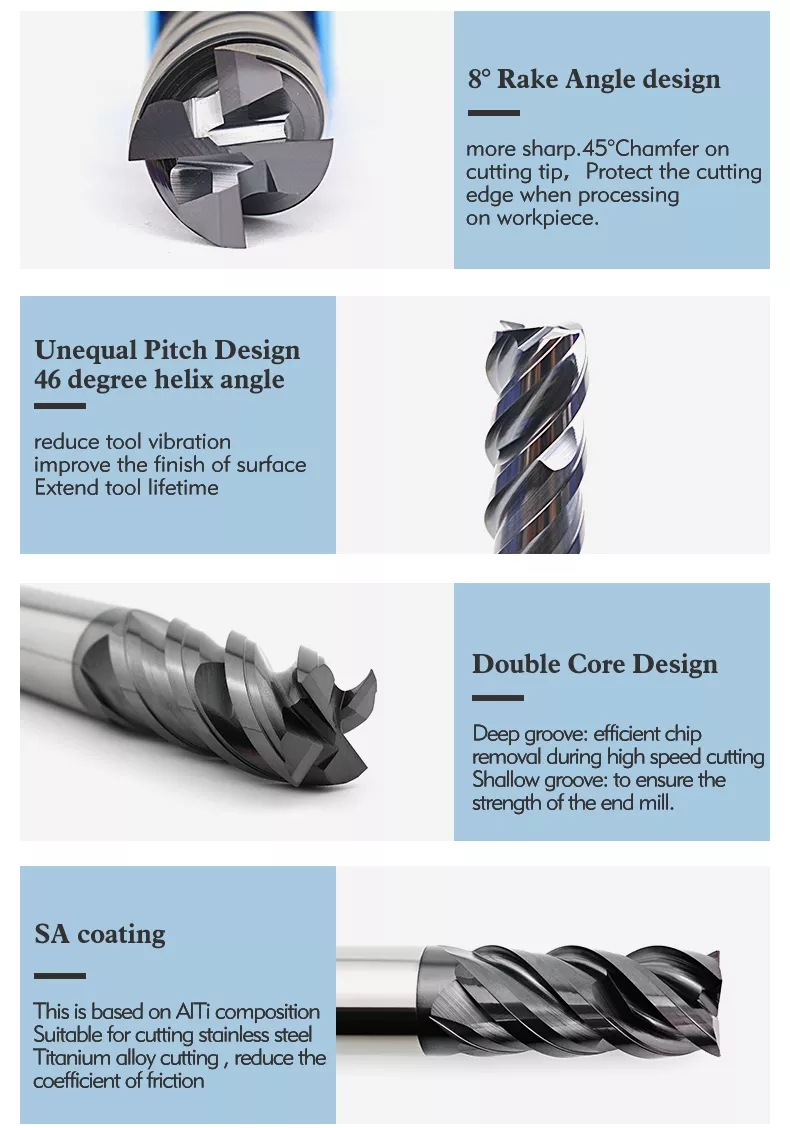

01 Negative antegrade design

Adopting the suitable design of the front angle, the cutting edge

strength and sharpness are taken into account. At the same time,

the large core diameter is used to enhance the tool rigidity and

make the cutting and chip removal stable.

02 Big chip space

Large capacity chip discharge has

strong cutting, dischar- ge chip smooth, can achieve high

efficiency processing.

03 Double edge belt design

Design of 35 °helical angle with double blade to reduce product

burr when milling cutter is more wear-resistant.

04 Chamfer easy to operate

Handle chamfering layout is easier for clamping.